Navigation

Quality Assurance

Quality lies at the core of everything we deliver, ensuring reliability you can count on.

Trust Zhongxin Green Energy to consistently exceed expectations, every time.

Committed to Providing the Most Reliable and Efficient Hybrid Inverter Solutions

To ensure the highest quality, we implement rigorous control measures at every stage of production. Our comprehensive quality assurance system covers every detail, from raw material selection to after-sales service, ensuring that our customers receive products of the utmost quality.

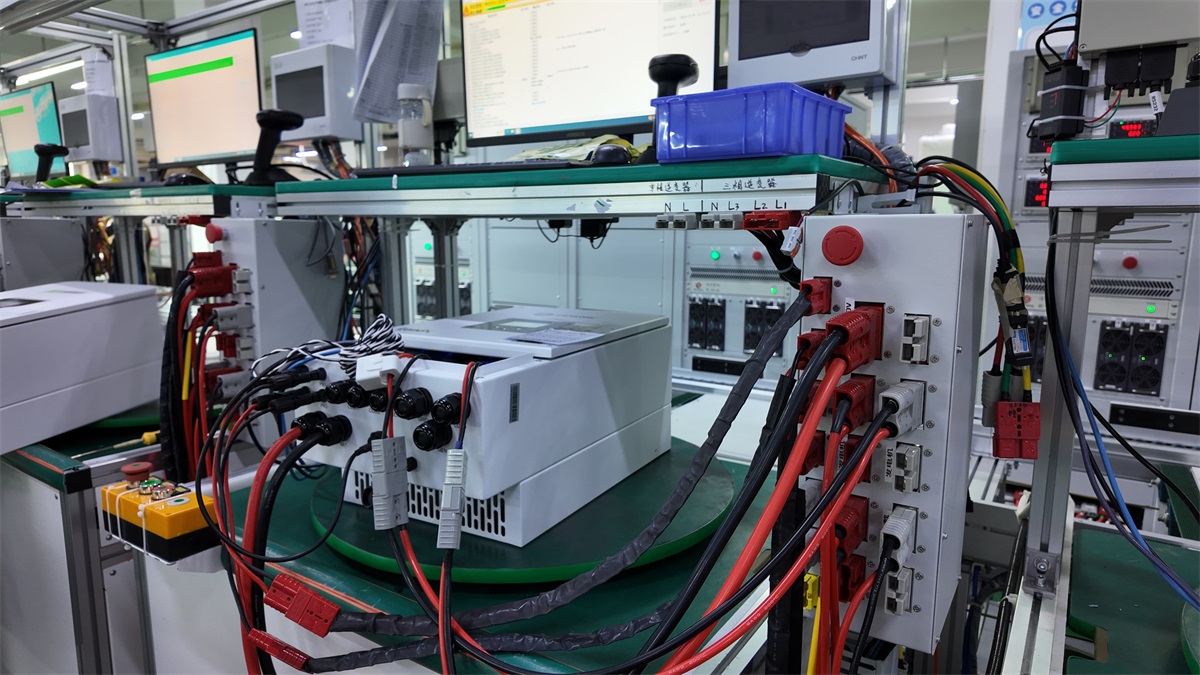

Strict Quality Control Process

Comprehensive and Whole Process Quality Control